10 Cool Things To Make With A CNC Machine

From pocket knives to board games, this a list of 10 fun and unique items you can create at home with a CNC machine!

Phone Case

CNC machines will allow you to create custom and durable cases for any type of cell phone. Regardless of how many jacks, speakers, ports or cameras the phone has, these machines enable you to make a case fitting any phone. Add some custom engravings or names on the case to really make your creation stand out.

- Material needed for cut: Wood.

Coasters

Are you looking for a simple project when you are first starting out with your CNC machine? Try creating some drink coasters for the family kitchen or coffee tables. Feel free to experiment with several different shapes, sizes and patterns.

- Material needed for cut: Wood.

Engravings

Do you want to make a keychain or some sort of keepsake for yourself or as a gift for a friend? Use your CNC machine to create a custom engraving. The beauty of this process is you can use pretty much any material you’d like for the creation. We suggest using wood or metal, but plastic and acrylic materials will work as well.

- Material needed for cut: Wood, Metal, Acrylic Or Plastic.

Pocket Knives

Much like creating a CNC yoyo, a pocket knife is a project that can take a long time and require precision at all times. Sharpening the metal will require focus, but it will make you more efficient with the machinery in the long run. Get the essential parts done first, then enjoy the creativity involved with engraving the outsides.

- Material needed for cut: Metal.

Board Games

Make your board game collection unique by creating pieces yourself. Use metal to make a chess board that is distinct from others. Games, such as chess, monopoly and snakes and ladders are perfect projects.

- Material needed for cut: Wood Or Metal.

Jewelry

While most DIY’ers tend to use metal for any jewelry creations, it is possible to turn wood into a piece of jewelry, as well. With CNC machinery, you can create rings, bracelets, earring, necklaces and more! Save money this holiday season by making your own jewelry for loved ones.

- Material needed for cut: Wood Or Metal.

Yoyo

This is one of the more unusual items one can make, yet one that can be passed down from generation to generation. Creating a CNC yoyo can be a bit difficult, though. You’ll want to weigh and balance the metal for optimum performance, while also making sure the string fits tightly around the ball bearings.

- Material needed for cut: Metal.

Signs

Typically, we suggest using wood as your material to create a sign with a CNC machine. Signs can create a great first impression as you enter a home or workplace. Make your area stand out with a wood sign that includes a greeting or quote.

- Material needed for cut: Wood.

Item Holder

No matter what you have in your home, garage or backyard, everyone could use an additional place to put some miscellaneous items. Too many times we will misplace keys, glasses, etc. Make sure that never happens again by building an item holder with your CNC machine. A nice piece of wood with several holes, rings and shelves could keep all of your small items organized.

- Material needed for cut: Wood.

Gift Boxes

Gift boxes are generally pretty simple to create, and the result can be truly magnificent. A well-crafted gift box can be used for years. Plus, you can turn the box into a storage box or container in addition to a gift box.

- Material needed for cut: Wood.

CNC Machine Shops Near Me

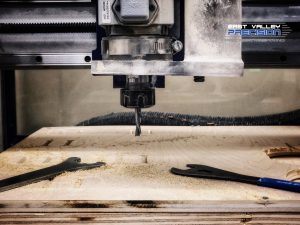

Do you want CNC machining services instead of attempting these projects on your own? Well, East Valley Precision, based in Chandler, Arizona, is here to help!

Equipped with over 40 years of experience, East Valley Precision has been offering top-notch customer service and machinery work throughout the valley. EVP specializes in CNC milling, turning, surface grinding, engineering and water jet cutting. This company also has extensive experience in machining aluminum, stainless steel, titanium and plastics. With customers from the medical, semiconductor and pharmaceutical industries, you can rest assured that any of your needs can be taken care of by EVP.

East Valley Precision – Custom Machinery Specialists

East Valley Precision offers custom CNC Machining in the Chandler, Arizona and surrounding areas. When you need precision CNC machining and milling contact East Valley Precision. Call us at 480-288-6601 for more information or use our form for a quote.