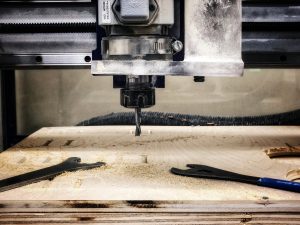

7 CNC Router Project Ideas

CNC routers continue to become more affordable for personal use. If you have a creative itch and some extra space in your garage or basement, try to tackle of few of these fun projects below!

1. Ukulele

For musicians and aspiring musicians, CNC routing projects can certainly come in handy. These routers are the best tool for any stringed instrument creations. This is because the routers deliver a level of accuracy that is unrivaled by other machinery. It is perfect for complex curves and inlays. Ukuleles can be created by Avid CNC Routers, which fit somewhere between commercial and recreational machinery.

2. Paddleboard

Perhaps you are more of an outdoorsman than a musician. Welp, CNC routers can still be used to aid your lifestyle, as well. A board can be finished with a single sheet of plywood, topped off with epoxy for waterproofing. A paddleboard, of course, can be very big depending on the person it is designed for, so these should be made using large commercial machines.

3. Paintbrush Holder

If you are an artist, a CNC routing hobby can pay off, as well. Use the CNC routers to add to your artistic needs. A paintbrush holder is a very simple project to take on with these machines. A small creation like this could also be used to generate some extra money on the side, as the material costs are minimal.

4. Man Cave Signs

Bring your man cave, garage area or your next outing to life by making some signs. Create some customized signs or even just making a wood template for others to engrave a message can spur a fun group activity.

5. Wall Maps

These can be great additions, regardless if you want to hang them in your home, garage or even office space. Wall maps are generally some of the cheapest projects you can make at home. Just purchase inexpensive plywood, following an outline for tracing and you should be done in no time!

6. Cell Phone Stand

We all endure the daily struggle of trying to stand our phone up on a table or in the car. Rid yourself of this problem by making a cell phone stand on your own. These items can be made quickly. Add some engravings to the stand and enjoy use of the product daily.

7. End Tables

Are you looking to spruce up your home’s interior? The answer to that request may be created by using your personal CNC router. Knockdown end tables can give your home a sleek and more modern look and appeal. Once the wood table is created, feel free to add glass or hardwood to the top.

CNC Router Services In Arizona

Equipped with over 40 years of experience, East Valley Precision has been offering top-notch customer service and machinery work throughout the valley. EVP, located in Chandler, Arizona, specializes in CNC milling, turning, surface grinding, engineering and water jet cutting. This company also has extensive experience in machining aluminum, stainless steel, titanium and plastics. With customers from the medical, semiconductor and pharmaceutical industries, you can rest assured that any of your needs can be taken care of by EVP.

CNC routers are perfect for the following tasks:

East Valley Precision – Custom Machinery Specialists

East Valley Precision offers custom CNC Machining in the Chandler, Arizona and surrounding areas. When you need precision CNC machining and milling contact East Valley Precision. Call us at 480-288-6601 for more information or use our form for a quote.