Close Tolerance Machining

Close tolerance machining is a meticulous CNC machining process intended to guarantee a component or part is created to precise specifications. When selecting a machine shop for CNC machining projects, possessing close tolerance machining and small parts machining proficiency is essential. It is especially vital when working with the avionics, aerospace, defense, entertainment and amusement, and high-performance racing sectors. Why is this type of CNC machining so important? It goes down like this. Would you want to hop on an airplane or get on a roller coaster manufactured with parts that were not created to precise specifications?

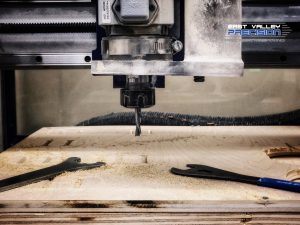

Close tolerance machining and small part machining are just a few of East Valley Precisions specialties. Private businesses, government entities and independent contractors depend on East Valley Precisions close tolerance machining and small part machining proficiencies to provide them with trustworthy parts and components. Our cutting-edge machinery is equipped with some of the most remarkable specs in the industry.

Skilled Machinists are a Must

We know a state-of-the-art machine needs to be operated by skilled and knowledgeable professionals. Not only are our close tolerance machining and small part machining team highly qualified, but they participate in continual training to keep up-to-date with the latest machining trends. East Valley Precisions feels proud about employing experienced machinists and staff. Whether your project necessitates the production of one or one thousand parts, you can depend on East Valley Precisions with all your close tolerance machining and/or small parts creating requirements.

Benefits Of Close Tolerance Machining Can Result in:

Better performance: Close tolerance components are required in complicated, critical assemblies such as pumps and valves. Since the parts have minimal differences, they provide continual performance during the lifespan of the end system.

Increased assembly efficiency: With uniform parts, it’s a lot easier to automate assembly and decrease the expense of adjustments.

Exchangeability: Since all the parts are close copies, they promote easy maintenance and part replacing. Technicians can easily remove a part and replace it with a new, identical part with negligible downtime or postponements.

Leak-proof seals: For precision components in hydraulic systems, valves, pumps, and pneumatic systems, the parts are required to fit together precisely to prevent leaks and spaces. Close tolerance machining methods create these parts that form a dependable seal.

Less resistance and wear: Close tolerance machining creates precise components that fit together correctly, without wear or resistance because of misalignment. Therefore, the final assembly lasts longer and operates more proficiently.

East Valley Precision – Custom Machinery Specialists

East Valley Precision offers custom CNC Machining in the Chandler, Arizona and surrounding areas. When you need precision CNC machining and milling contact East Valley Precision. Call us at 480-288-6601 for more information or use our form for a quote.

How Much Is A CNC Machine?

There are thousands of CNC machines available on the market today, with costs ranging all the way from $150 to $300,000. Prices will vary based on size of the machine, quality and speed.

Average CNC Machine Costs

Here are the typical costs for several different personal CNC machines:

- Entry Level Desktop CNC Router: $150-$500

- Hobby CNC Machine: $1,000-$3,000

- Small CNC Lathe: $5,000

- Entry Level 2 Axis Lathe: $15,000-$50,000

- Professional CNC Machine: $5,000-$100,000

- Entry Level 3 Axis Mill: $50,000-$100,000

- Production Mill: $100,000-$500,000

- Production Lathe: $50,000-$300,000

Obviously, there is a wide range of costs associated with CNC machining. CNC machines that are used for wood are significantly cheaper than machines used for metal. This is because of the ease of cutting wood compared to other tougher materials. Also, the tolerance on metal is much tighter, so there is generally no room for error.

CNC Machine Cost Factors

These are the main factors affecting the overall cost of CNC machines:

Size

In the CNC machining world size refers to the length of the cutting end of the machine. This travels along each axis, including X, Y and Z. Generally, the larger range of motion, the more the machine will cost.

Speed

Cutting speed directly impacts the efficiency of production. Rapid motion speed (RMS) is a measurement of the speed at which the CNC repositions itself after cuts. The fastest CNC machines tend to have a RMS of 1,000 inches per minute.

Power

CNC power is measured in terms of specs such as torque and spindle RPM. Larger professional grads CNCs are rated based on size of the servo motors.

Quality

Quality can refer to the accuracy and tolerance of the CNC machine. Of course, accuracy, tolerance and repeatability all come with high price tags.

Number Of Axes

The cost will increase as the number of axes go up. A 6 axis machine will move quicker than a 5 axis machine, and it will undoubtedly cost more, as well.

What Can A CNC Machine Do?

The goal of the CNC machine is to make precise cuts into pieces of metal for industrial uses. Additionally, the systems inside the CNC include:

- Wood Routing

- Turret Punching

- Wire-Bending Abilities

- Foam Cutting

- Laser Etching and Cutting

- Cylindrical Grinding

- 3D Printing

- Glass Cutting

- Embroidery Machines

CNC machines can efficiently perform intricate cuts in a matter of minutes. However, it is dependent on how your CNC machine is programmed to function and act within the specified code. The machine only operates according to the instructions given to it by the program within the system. The CNC machine should have the code programmed inside, ready to start designing products. The final result will emerge once the program and shaping process has been completed.

CNC Machining Services

Equipped with over 40 years of experience, East Valley Precision has been offering top-notch customer service and machinery work throughout the valley. EVP, located in Chandler, Arizona, specializes in CNC milling, turning, surface grinding, engineering and water jet cutting. This company also has extensive experience in machining aluminum, stainless steel, titanium and plastics. With customers from the medical, semiconductor and pharmaceutical industries, you can rest assured that any of your needs can be taken care of by EVP.

East Valley Precision – Custom Machinery Specialists

East Valley Precision offers custom CNC Machining in the Chandler, Arizona and surrounding areas. When you need precision CNC machining and milling contact East Valley Precision. Call us at 480-288-6601 for more information or use our form for a quote.

What Is CNC Milling?

If you are searching for “what is cnc milling“, East Valley Precision is here to help!

What Is A CNC Machine?

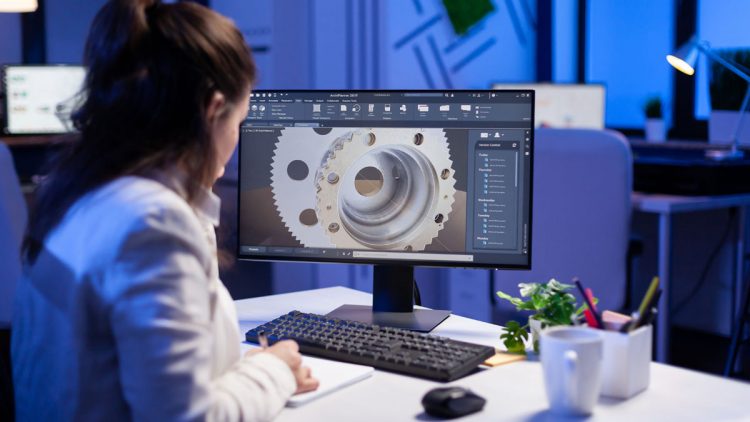

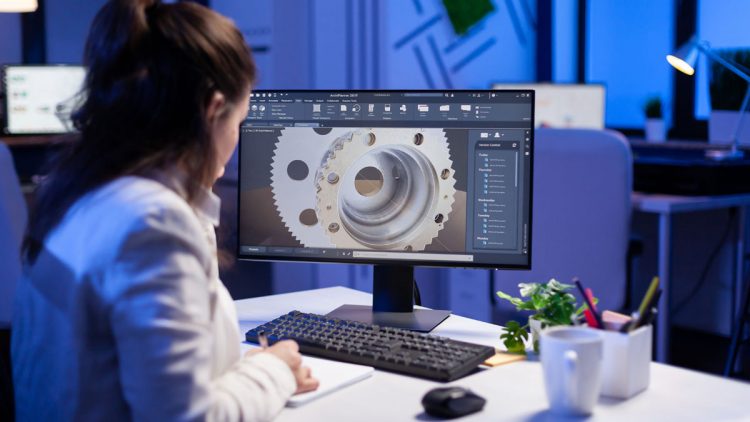

CNC stands for Computer Numerical Control. This completely automated motion control machine has three components, including a motion system, command function and feedback system. CNC machining is simply the process of using a computer-operated machine to produce parts of a solid material into a desired shape.

What Is A CNC Milling Machine?

Milling is the process of drilling and cutting materials, such as metal or wood. A milling machine will utilize a tool called a milling cutter to perform its duty, regardless of whether it is operated through CNC or manually. This tool is held in a spindle and can vary in size, depending on the project’s needs.

The CNC milling machine’s ability to cut in different angles and move along different axes is what separates it from other drilling machines. To account for the various angles and axes, there are a few different milling machines, including:

- 2-axis milling machines.

- 3-axis milling machines.

- 4-axis milling machines.

- 5-axis milling machines.

- CNC milling machines (2-5 axis).

CNC Milling Machine Types

Despite the axis classifications, there are other ways to define the milling machine types. For example, a vertical mill will feature 3-axis with a table, arm and attached spindle. Both the table and arm will be connected to a vertical column with this model of machine. The table will then move up and down along the z-axis, meeting the arm.

With a turret vertical mill version, the spindle will be stationary and the table will move along both the x and y-axis. A bed vertical mill, meanwhile, can only move along the x-axis. A horizontal mill is nearly the same as the vertical mill, yet only differs with the spindle oriented horizontally. A knee mill features an adjustable knee, enabling columns to move up and down.

CNC Milling Tool Types

Each different milling machine will utilize a variety of specialized tools. Some larger machines can even change tools during a cut. If you choose an overly strong steel tool for a wood cut, you could end up with a damaged product. Wood tools used for steel cuts can end up breaking the tool, altogether. A milling cutter is the most basic tool. Cutters will vary in shape and size for precise cuts.

What Can A CNC Milling Machine Do?

The goal of the CNC milling machine is to make precise cuts into pieces of metal and metal for industrial uses. Additionally, these systems can be used for the following:

- Woodworking.

- Furniture.

- Instruments.

- Cabinets.

- Aluminum.

- Signs.

- Sculptures.

CNC machines can efficiently cut the following materials:

- Steel.

- Titanium.

- Copper.

- Zinc.

- PVC.

- Plywood.

- Stone.

CNC Milling Services

Equipped with over 40 years of experience, East Valley Precision has been offering top-notch customer service and machinery work throughout the valley. EVP, located in Chandler, Arizona, specializes in CNC milling, turning, surface grinding, engineering and water jet cutting. This company also has extensive experience in machining aluminum, stainless steel, titanium and plastics. With customers from the medical, semiconductor and pharmaceutical industries, you can rest assured that any of your needs can be taken care of by EVP.

East Valley Precision – Custom Machinery Specialists

East Valley Precision offers custom CNC Machining in the Chandler, Arizona and surrounding areas. When you need precision CNC machining and milling contact East Valley Precision. Call us at 480-288-6601 for more information or use our form for a quote.

CNC Router Services Near Me

If you are searching for “cnc router services near me” or “cnc shop near me“, look no further than East Valley Precision.

This article will detail the various CNC router services and processes commonly used today.

CNC Router Services

Equipped with over 40 years of experience, East Valley Precision has been offering top-notch customer service and machinery work throughout the valley. EVP, located in Chandler, Arizona, specializes in CNC milling, turning, surface grinding, engineering and water jet cutting. This company also has extensive experience in machining aluminum, stainless steel, titanium and plastics. With customers from the medical, semiconductor and pharmaceutical industries, you can rest assured that any of your needs can be taken care of by EVP.

CNC routers are perfect for the following tasks:

CNC Router Machines

There are great examples of CNC routers being able to manipulate all forms of materials. A lot of woodworkers tend to leverage CNC routers in their work to sever and mold all types of wood. If you would like to design any chairs, etc, CNC routers are a necessity. You can do all sorts of shaping and sliding to make clean cuts. With the cuts and measurements, you can easily craft bolts and screws, meshing them together to create amazing pieces of furniture.

Comparatively to other CNC machinery, these CNC routers are extremely effective at crafting exact materials. These routers can be typically found in manufacturing houses and be purchased for other private purposes.

CNC Router Process

CNC machinery runs on a series of pre-programmed scripts and commands. When using these machines, follow this 3-step process:

- A Vector image is created which does not have a G-Code attached. This vector is a form of a DXF extension that has details compared to the x, y and z axis, which help determine the resulting image that will be produced.

- Take the produced vector from before and translate this into a G-Code.

- A New CNC system will then take that script and formatted G-code, then translating that inside the machine’s system.

CNC Routing Gallery

Take a look below at some of East Valley Precision’s latest projects:

Types Of CNC Machine

CNC machines were originally controlled by analog computers, and later, digital computers.

There is a whole line of CNC machines that are entirely electronic. Most commonly CNC’s include some form of ultrasonic welding, laser etching, and hole crafting. Here is a list of the more common CNC machines being used today:

CNC Mill

CNC milling is a machining method that utilizes computerized controls and spinning multi-point cutting devices to remove material from a workpiece. The end result will be custom-designed parts or products.

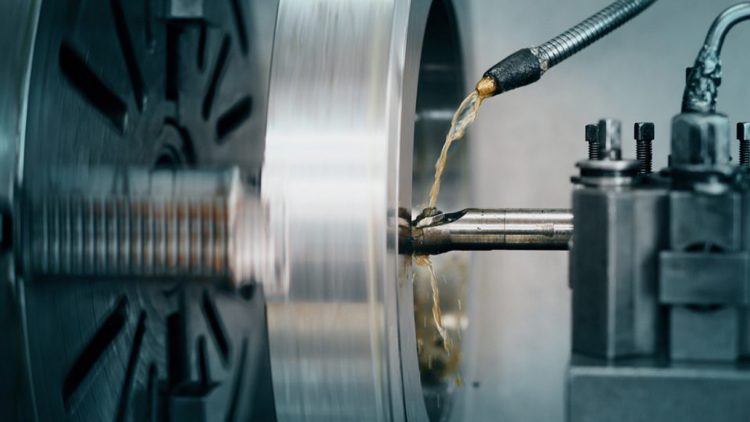

Lathes

This particular machine rotates a piece through an axis of rotation (x and y respectively) to perform various processes. These tasks include cutting, knurling, sanding, drilling, deformations and turning.

Plasma Etching/Cutting

Plasma Etching is the elimination of silicon, plastic, or other non-metallic materials using plasma which is produced by exciting ions in a gas; typically oxygen and CF4. Those ions crash into the material at an atomic level and remove it without needing chemical acids.

Electric Discharging Machine (EDM)

Electrical discharge machines (EDM) use a nontraditional technique where material is removed from a workpiece via thermal energy. A lot like processes such as laser cutting, EDM doesn’t require mechanical pressure in the removal process.

Water Jet Cutters

A waterjet cutter uses high-pressure streams of water to eat away at a slender line in the piecework. Used for cutting a wide range of material, including tool steel and titanium to foam, a granular abrasive is implemented to the waterjet. This will increase the jet’s cutting power. Since the abrasive is implemented at the nozzle, it is easy to change between just water and abrasive waterjet cutting.

East Valley Precision – Custom Machinery Specialists

East Valley Precision offers custom CNC Machining in the Chandler, Arizona and surrounding areas. When you need precision CNC machining and milling contact East Valley Precision. Call us at 480-288-6601 for more information or use our form for a quote.

What are CNC Routers?

CNC (Computer Numerical Control) Routers help to cut through all forms of surfaces, such as wood, foam, steel, and even different types of composites. These routers are very comparable to CNC mills, when it comes to computer functionalities that can be used inside the computer by numerical orders that route paths enabling machines to work properly. CNC routers reduce the general amount of waste and increases the rate of productivity. If you are searching for “cnc routers” or “what are cnc routers,” then this post is for you!

How Do CNC Routers Work?

CNC machinery runs on a series of pre-programmed scripts and commands. When using these machines, follow this 3-step process:

- A Vector image is created which does not have a G-Code attached. This vector is a form of a DXF extension that has details compared to the x, y and z axis, which help determine the resulting image that will be produced.

- Take the produced vector from before and translate this into a G-Code.

- A New CNC system will then take that script and formatted G-code, then translating that inside the machine’s system.

How CNC Routers Are Used

There are great examples of CNC routers being able to manipulate all forms of materials. A lot of woodworkers tend to leverage CNC routers in their work to sever and mold all types of wood. If you would like to design any chairs, etc, CNC routers are a necessity. You can do all sorts of shaping and sliding to make clean cuts. With the cuts and measurements, you can easily craft bolts and screws, meshing them together to create amazing pieces of furniture.

Comparatively to other CNC machinery, these CNC routers are extremely effective at crafting exact materials. These routers can be typically found in manufacturing houses and be purchased for other private purposes.

CNC Router Details

It depends on the age of the model of the CNC router. Some can be extremely large, and really take up a lot of space. Although, some of the new models of CNC routers are much more convenient in size, generally placed on a modern table. Machines for private use aren’t nearly as powerful as industrial models, but they can be used with the access of a computer in the comfort of your own home. Once accessed, you can start to program the CNC router to do all kinds of different functions to produce whatever you desire.

Why Buy A CNC Router?

Capacity

This, of course, will boil down to the size of the project you are beginning. The bigger the project, the heavier duty the CNC router should be to handle this. CNC routers of the average size of 4×8 are very feasible for beginners looking to learn about CNC routers. Its very common for many college students to have one of their own and or homeowners to have one for smaller projects.

Life Span and Strength

Of course, not all CNC router machinery is going to perform the same for longer set durations and periods. These machines over time tend to wear down like brake pads in a car, as they work with a lot of friction.

Value

With all investments, you would love to understand the value in which your getting in return. Depending on the model, you may get different accessories and parts at discounted rates. Some machines come with prebuilt different software designs, requiring you to purchase different materials to accomplish different jobs.

If you need help with picking a CNC router and choosing one, you can always contact us for advice and help!

CNC Machine Shop Near Me

Equipped with over 40 years of experience, East Valley Precision has been offering top-notch customer service and machinery work throughout the valley. EVP, located in Chandler, Arizona, specializes in CNC milling, turning, surface grinding, engineering and water jet cutting. This company also has extensive experience in machining aluminum, stainless steel, titanium and plastics. With customers from the medical, semiconductor and pharmaceutical industries, you can rest assured that any of your needs can be taken care of by EVP.

CNC Machining can handle the following:

- Wood routing

- Turret Punching

- Wire-Bending Abilities

- Foam Cutting

- Laser Etching and Cutting

- Cylindrical Grinding

- 3D Printing

- Glass Cutting

- Embroidery Machines

East Valley Precision – Custom Machinery Specialists

East Valley Precision offers custom CNC Machining in the Chandler, Arizona and surrounding areas. When you need precision CNC machining and milling contact East Valley Precision. Call us at 480-288-6601 for more information or use our form for a quote.

Types Of CNC Machine

CNC machines are automated motion control machines that consist of three components: a motion system, feedback system and a command function. The goal of CNC (Computer Numerical Control) is to make precise cuts of metal pieces for industrial use. There are several different kinds of CNC machines, though. If you are searching online for “types of cnc machine,” then this post is for you!

CNC Machine Types

Original numerical control machines date all the way back to the 1940s. Back then, using a motor was essential for other devices’ movement. While technology advanced, this helped the CNC machine lead the industry in a different direction earlier than expected. CNC machines were originally controlled by analog computers, and later, digital computers.

There is a whole line of CNC machines that are entirely electronic. Most commonly, CNC’s include some form of ultrasonic welding, laser etching, and hole crafting. Here is a list of the more common CNC machines being used today:

CNC Milling

CNC milling is a machining method that utilizes computerized controls and spinning multi-point cutting devices to remove material from a workpiece. This process will rapidly cut solid metal and plastics into smaller and final parts. Smooth finishes are possible, as well as producing 2D or 3D shapes. CNC milling machines can create parts for mechanisms, engines, enclosures and more. The end result will be custom-designed parts or products.

CNC Lathes

This particular machine rotates a piece through an axis of rotation (x and y respectively) to perform various processes. These tasks include cutting, knurling, sanding, drilling, deformations and turning. A CNC lathe is used to cut away any excess materials by rotating a piece on a spindle. Different drilling bills and cutters will chip away at the material(s). CNC lathes can be configured to cut precisely and efficiently. Such precise cuts would not be possible if done manually.

CNC Plasma Cutter

Plasma Etching is the elimination of silicon, plastic, or other non-metallic materials using plasma which is produced by exciting ions in a gas; typically oxygen and CF4. Those ions crash into the material at an atomic level and remove it without needing chemical acids. Within CNC plasma cutters, gas will be blown from a nozzle to the surface at very high speeds. Gas is then converted into plasma, with a temperature up to 50,000 degrees.

CNC Laser Cutter

CNC laser cutters are very similar to CNC plasma cutting machines. The biggest difference between the two, of course, is the use of the laser for cutting purposes. Lasers are tremendous tools used to cut metals, hardwoods and plastic materials. The intensity of the laser can be adjusted depending on the strength and density of the materials that needs to be cut.

Electric Discharging Machine (EDM)

Electrical discharge machines (EDM) use a nontraditional technique where material is removed from a workpiece via thermal energy. A lot like processes such as laser cutting, EDM doesn’t require mechanical pressure in the removal process.

The Two Different Sub Types Of EDM’s:

- In wire electrical discharge machines, a slim single-strand metal wire, is slipped across the piece. This wire will be submerged in a bath of dielectric fluid, generally deionized water.

- Electrical Discharge Machine or sinker EDM machining processes an electrically charged electrode calibrated to a particular configuration to burn the configuration of the electrode into a metal element. This type of process is usually used to produce molds and dies.

CNC Machine Shop

Equipped with over 40 years of experience, East Valley Precision has been offering top-notch customer service and machinery work throughout the valley. EVP specializes in CNC milling, turning, surface grinding, engineering and water jet cutting. This company also has extensive experience in machining aluminum, stainless steel, titanium and plastics. With customers from the medical, semiconductor and pharmaceutical industries, you can rest assured that any of your needs can be taken care of by EVP.

East Valley Precision – Custom Machinery Specialists

East Valley Precision offers custom CNC Machining in the Chandler, Arizona and surrounding areas. When you need precision CNC machining and milling contact East Valley Precision. Call us at 480-288-6601 for more information or use our form for a quote.