What Is Precision Machining?

We live in a time when advancements in contemporary manufacturing, particularly in the last 20 years, have advanced quickly. And the introduction of precision machining has been at the forefront of many of our manufacturing innovations.

Many of the parts, tools, components, and equipment that we use on a daily basis are made in large part by precision machining.

Precision machining is essential to the construction of nearly every piece of machinery, product, or equipment that needs a high degree of accuracy, from the small components used in electronics to the parts found in cars, boats, rockets, and skyscrapers.

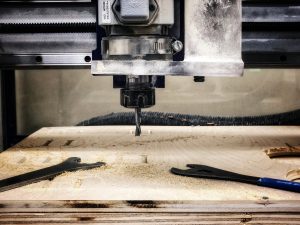

Precision machining is the process of shaping, cutting, and removing excess material from a workpiece to meet the dimensional requirements for a finished part or component using computer numerically controlled machining and milling tools under the supervision of a precision machinist.

There can be a reasonable amount of variation between the final dimensions of any two products because no two parts can be made exactly alike.

Tolerances are a set of quantifiable values that define this acceptable deviation.

Because determining the ideal tolerance directly affects turnaround time and manufacturing costs, tolerances are essential to the manufacturing process.

Additional Typical Definitions and Functions of Machining

By definition, a precision machine is a high-precision machine tool used to attain extremely high levels of accuracy. Machines used in precision manufacturing include CNC milling machines, lathes, grinders, cutting tools (such as drill presses and saws), and even high-speed robotics.

The process of removing excess raw material from a workpiece while maintaining the exact tolerances needed to produce a final product is known as precision manufacturing.

Definition of CNC Manufacturing: Computer numerical control (CNC) manufacturing is a broad category of automated manufacturing procedures in which raw materials are cut, milled, and shaped by CNC machining tools in accordance with CAD software specifications.

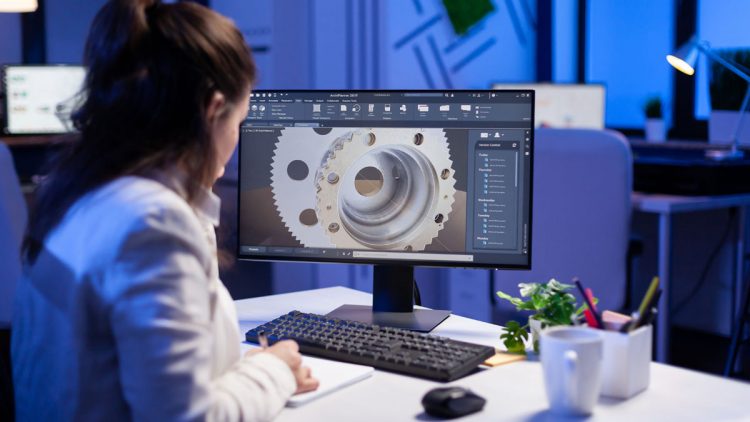

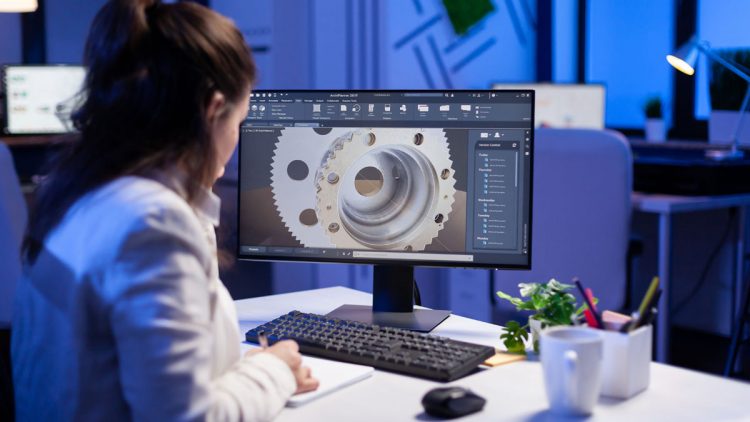

The product’s blueprint is created using computer-aided design (CAD) software, which also helps with design creation, analysis, and optimization. Computer-aided manufacturing (CAM) software then converts these specifications into automated manufacturing instructions for CNC machines.

What Are the Applications of Precision Machining?

When parts need to be machined with a high degree of accuracy and uniformity, precision machining is a very effective and precise manufacturing process. High-precision CNC machining tools are used to meet standards when a part requires tighter tolerances.

Raw Materials Frequently Used in Precision Machining

Modern manufacturing uses a broad range of raw materials to satisfy industry-wide quality control requirements and standard machining tolerances.

A list of frequently used raw materials, such as engineered plastics, can help you achieve the tolerance and uniformity you’re looking for, since a part’s tolerance is greatly influenced by the composition of the material.

These consist of materials like:

Seven Typical Materials for Accurate Machining

Stainless steel’s strength, machinability, corrosion resistance, and versatility

Aluminum is a lightweight, affordable, corrosion-resistant, and tolerant material.

Brass: Offers a smooth, clean finish and retains threads and tolerances well.

Titanium’s strength to weight ratio, resistance to corrosion, and extreme heat

Copper’s inherent resistance to corrosion, electrical conductivity, and durability

Basic Plastics: incredibly affordable, adaptable, long-lasting, and easily injected

Polymer Plastics: strength, cleaning capabilities, and resistance to corrosion and abrasion

Applications of Precision Machining (By Industry)

Precision machining’s broad applications and exacting accuracy are essential to a large portion of contemporary manufacturing. Let’s examine how precision machining affects the following industries to better appreciate its significance:

The Aerospace Sector

Because precision machining can achieve extremely high tolerances and accuracies, it has been the foundation of aerospace innovation. Precision is essential in situations where a single mistake could cause significant harm. Additionally, many of the components that this industry relies on are made using CNC precision machining processes, including:

Systems for navigation

Panels for interior walls

Ports for landing gear

Bushings for the Automotive Sector

Precision machining techniques are frequently used to design and develop the precise specifications for a part or component needed before being added to the assembly line, especially with the rise in electric vehicles and advancements at the forefront of the automotive industry. Transmissions, wheels, water pumps, and engine blocks are typical examples of machined parts.

Defense and Military Sector

Precision machining has never been as common in the military and defense industries as it is in the development of composite skins for the F35 fighter jet, communication components for SAT radios, and prototyping and ammunition. The depth of parts and accuracy needed are enormous, and CNC machining is a good fit because different countries use different military and defense schematics.

The Medical Sector

To create breakthroughs that enhance our health and quality of life, the medical sector depends on technological and medical equipment innovations. Many of the parts used in the medical field would not be accessible without precision machining. MRI scanners, surgical instruments, implants, orthotic devices, secure enclosures, and research apparatus are typical examples.

East Valley Precision – Custom Machinery Specialists

East Valley Precision offers custom CNC Machining in the Chandler, Arizona and surrounding areas. When you need precision CNC machining and milling contact East Valley Precision. Call us at 480-288-6601 for more information or use our form for a quote.

Wood Lathe Diagram

Here’s a labeled diagram of a typical wood lathe:

🛠 Main Components of a Wood Lathe:

- Headstock – Houses the motor and spindle, which rotates the wood.

- Spindle – The rotating shaft that holds the workpiece (for spindle turning) or a faceplate/chuck (for bowl turning).

- Tailstock – Supports the end of the workpiece and can hold a live center or drill bit.

- Tool Rest – Adjustable support for guiding your turning tools.

- Bed – The horizontal frame connecting the headstock and tailstock.

- Banjo – The movable base that holds the tool rest and allows for positioning adjustments.

- Speed Control – Adjusts the spindle speed for different turning tasks.

Since I can’t directly send images, you can easily find a labeled diagram by searching “wood lathe diagram” online, or I can generate an illustration for you. Let me know how you’d like to proceed!

Parts of a Wood Lathe

Parts for Wood Lathes

Recognizing every component of a wood lathe is essential, particularly when operating the machine for the first time.

The components of a wood lathe

Here is a comprehensive list of things to be aware of:

Dimensions

Size of Headstock, Spindle, Toolrest, Tailstock, Motors, and Bed Accessories

Two factors determine the size of a lathe. One factor is calculating the distance between the spindle’s center and the bed’s surface, which establishes the maximum diameter limit. Measuring the distance between the spindle’s end and the tailstock’s inside end is another method of determining size. This will let you know how long the piece ought to be.

Headstock

When looking at the lathe from the front, the headstock is on the left. The headstock, which generates power by applying the motor to the wood, is essentially the lathe’s business end. While some headstocks are fixed in place, others have 360-degree rotation. Additionally, some headstocks have the ability to run the full length of the lathe. You can turn larger diameter pieces with any of these options.

The Spindle

Wood is fastened to spindles, which are propelled by belts and pulleys. On the outside of the lathe, the spindle is threaded. It is situated here to accommodate a variety of accessories and attachments. Usually, a particular taper holds the accessories in place. Tapers come in different sizes.

The toolrest

The toolrest is movable along the length of the bed and has height and rotational adjustments. To achieve this, first loosen the banjo and then tighten it to the desired position.

Automobiles

While some modern lathes use hydraulic motors, others use electric motors. Fixed speed, variable speed, A/C, D/C, electronic braking, and single rotation are all possible configurations for the motors. Drive-through pulleys are used in many motors.

The Tailstock

Although it can be moved and adjusted if necessary, the tailstock is located farthest from the headstock. A hand wheel or screw mechanism can be used to drive a movable component. In order to accommodate accessories, this part is typically hollow and equipped with a morse taper.

The Bed

Everything is mounted on the bed, which is the section of the lathe. Round tubes, machined cast iron, steel, or wood can be used to build the bed.

Add-ons

The following accessories might be included with your lathe: a faceplate, wrenches, a knockout bar, and a center for the tailstock. You can include an additional toolrest in your application.

Water Jet Cutting Services

East Valley Precision offers water jet cutting services near Phoenix & Chandler, Arizona. Contact East Valley Precision today!

Precision Machining

Precision machining is a machining technique that utilizes CNC machining and milling tools with the supervision of a machinist to cut, shape and remove excessive materials from a work piece to meet the dimensional details for a finished component or part.

Because no 2 parts can be made to match each other, a permissible level of deviation is permitted to exist between any 2 products’ finished dimensions. This permissible deviation is viewed as a set of measurable values referred to as tolerances. Tolerance plays an important role in manufacturing processes, as finding the correct degree of tolerance has a direct influence on turnaround time and manufacturing expenses.

Other Common Precision Machining Definitions and Roles

- Precision Machine: A high-precision machining tool that is used to achieve extreme degrees of accuracy. For instance machines used in precision manufacturing comprise of grinders, lathes, CNC milling machines, a cutting tool and possibly high-speed automation.

- Precision Manufacturing: Precision manufacturing is defined as a technique that removes excessive raw material from a work piece while fulfilling the tight tolerances required to create a final product.

- CNC Manufacturing: CNC manufacturing involves a broad range of automated manufacturing processes where CNC machining devices cut, shape, and mill raw materials to fulfill provisions defined in CAD software.

- Computer-Aided Design: CAD software aids in the development, review, and optimization of a design while taking the role as the product’s blueprint in which Computer-Aided Manufacturing (CAM) software then converts those specifications into automated manufacturing guidelines for CNC machines.

What is Precision Machining Used For?

Precision machining is an extremely precise and efficient manufacturing process that is utilized when parts are required to be machined with a significant degree of precision and regularity. When a part requires strict tolerances, then high-precision CNC machining devices are used to fulfill set standards.

Precision Machining Applications (By Industry)

A lot of today’s manufacturing relies on the wide-scale applications and extreme accuracy of precision machining. The below industries benefit from precision machining:

- Aerospace Industry

- Automotive Industry

- Military and Defense Industry

- Medical Industry

Locating the Right Precision Machining Company

By practice and definition, precision machining is one of the most ideal ways to manufacture complex or one-off parts. Subject to your manufacturing requirements, a reputable precision machining company can assist you in designing, sourcing, and manufacturing high-precision parts that fulfill your specifications. At East Valley Precision, we’ve been machining quality parts since 2004 while our quality control guarantee keeps you safeguarded.

East Valley Precision – Custom Machinery Specialists

East Valley Precision offers custom CNC Machining in the Chandler, Arizona and surrounding areas. When you need precision CNC machining and milling contact East Valley Precision. Call us at 480-288-6601 for more information or use our form for a quote.

What Can You Make With A CNC Machine?

From pocket knives to board games, this a list of 10 fun and unique items you can make at home with a CNC machine!

1. Phone Case

CNC machines will allow you to create custom and durable cases for any type of cell phone. Regardless of how many jacks, speakers, ports or cameras the phone has, these machines enable you to make a case fitting any phone. Add some custom engravings or names on the case to really make your creation stand out.

- Material needed for cut: Wood.

2. Coasters

Are you looking for a simple project when you are first starting out with your CNC machine? Try creating some drink coasters for the family kitchen or coffee tables. Feel free to experiment with several different shapes, sizes and patterns.

- Material needed for cut: Wood.

3. Engravings

Do you want to make a keychain or some sort of keepsake for yourself or as a gift for a friend? Use your CNC machine to create a custom engraving. The beauty of this process is you can use pretty much any material you’d like for the creation. We suggest using wood or metal, but plastic and acrylic materials will work as well.

- Material needed for cut: Wood, Metal, Acrylic Or Plastic.

4. Pocket Knives

Much like creating a CNC yoyo, a pocket knife is a project that can take a long time and require precision at all times. Sharpening the metal will require focus, but it will make you more efficient with the machinery in the long run. Get the essential parts done first, then enjoy the creativity involved with engraving the outsides.

- Material needed for cut: Metal.

5. Board Games

Make your board game collection unique by creating pieces yourself. Use metal to make a chess board that is distinct from others. Games, such as chess, monopoly and snakes and ladders are perfect projects.

- Material needed for cut: Wood Or Metal.

6. Jewelry

While most DIY’ers tend to use metal for any jewelry creations, it is possible to turn wood into a piece of jewelry, as well. With CNC machinery, you can create rings, bracelets, earring, necklaces and more! Save money this holiday season by making your own jewelry for loved ones.

- Material needed for cut: Wood Or Metal.

7. Yoyo

This is one of the more unusual items one can make, yet one that can be passed down from generation to generation. Creating a CNC yoyo can be a bit difficult, though. You’ll want to weigh and balance the metal for optimum performance, while also making sure the string fits tightly around the ball bearings.

- Material needed for cut: Metal.

8. Signs

Typically, we suggest using wood as your material to create a sign with a CNC machine. Signs can create a great first impression as you enter a home or workplace. Make your area stand out with a wood sign that includes a greeting or quote.

- Material needed for cut: Wood.

9. Item Holder

No matter what you have in your home, garage or backyard, everyone could use an additional place to put some miscellaneous items. Too many times we will misplace keys, glasses, etc. Make sure that never happens again by building an item holder with your CNC machine. A nice piece of wood with several holes, rings and shelves could keep all of your small items organized.

- Material needed for cut: Wood.

10. Gift Boxes

Gift boxes are generally pretty simple to create, and the result can be truly magnificent. A well-crafted gift box can be used for years. Plus, you can turn the box into a storage box or container in addition to a gift box.

- Material needed for cut: Wood.

CNC Machine Shops Near Me

Do you want CNC machining services instead of attempting these projects on your own? Well, East Valley Precision, based in Chandler, Arizona, is here to help!

Equipped with over 40 years of experience, East Valley Precision has been offering top-notch customer service and machinery work throughout the valley. EVP specializes in CNC milling, turning, surface grinding, engineering and water jet cutting. This company also has extensive experience in machining aluminum, stainless steel, titanium and plastics. With customers from the medical, semiconductor and pharmaceutical industries, you can rest assured that any of your needs can be taken care of by EVP.

East Valley Precision – Custom Machinery Specialists

East Valley Precision offers custom CNC Machining in the Chandler, Arizona and surrounding areas. When you need precision CNC machining and milling contact East Valley Precision. Call us at 480-288-6601 for more information or use our form for a quote.

How To Use A CNC Machine

CNC machines are automated motion control machines that consist of three components: a motion system, feedback system and a command function. The goal of CNC (Computer Numerical Control) is to make precise cuts of metal pieces for industrial use. So, how do you operate these machines? Let’s take a look!

Materials Needed

The first step toward using a CNC machine is figuring out what you want to use it for. Are the materials soft, such as plastic or wood, or are you working with metal? The type of material you are using will dictate the type of machine needed. If you are working with wood, then a CNC router should be used, while a CNC milling machine is necessary for any metal projects.

CNC Software

Every CNC machine uses computer software to control their movements. The software entails a three-step process. Parts are drawn in a CAD program (computer-aided design), then a CAM program (computer-aided manufacturing) will convert the drawing into a code called g-code. The machine will then read the g-code and complete the formation of the part. Some machinists will write the g-code directly into the machine, but most individuals still rely on CAM programs.

CAD Programs

CAD programs are available to buy from the majority of software shops, with other free versions found online. It’s a good idea to try free programs before investing in more advanced packages. Use the CAD program gridlines when drawing to be specific about your measurements.

CAM Programs

After you have completed the drawing, import the file into a CAM program. At this point, things become more complex since you have to tell the software what types of tools to use and how deep the cuts need to be. Once you have defined the tools, it’s time to create a g-code for the machine to read. The g-code will be automatically created once you have finished inputting the information.

G-Code

Commercial CNC machines will transfer the g-code directly to the machine, while smaller ones are typically run by external PCs. These should have a machine control program that uploads the g-code to the program, starting the final process. If you wish to type the g-code directly into the machine, then find the g-code reference for the machine. You can type the command straight into the program, bypassing both the CAD and CAM processes.

CNC Machine Types

There is a whole line of CNC machines that are entirely electronic. Most commonly, CNC’s include some form of ultrasonic welding, laser etching, and hole crafting. Here is a list of the more common CNC machines being used today:

CNC Milling

CNC milling is a machining method that utilizes computerized controls and spinning multi-point cutting devices to remove material from a workpiece. This process will rapidly cut solid metal and plastics into smaller and final parts. Smooth finishes are possible, as well as producing 2D or 3D shapes. CNC milling machines can create parts for mechanisms, engines, enclosures and more. The end result will be custom-designed parts or products.

CNC Lathes

This particular machine rotates a piece through an axis of rotation (x and y respectively) to perform various processes. These tasks include cutting, knurling, sanding, drilling, deformations and turning. A CNC lathe is used to cut away any excess materials by rotating a piece on a spindle. Different drilling bills and cutters will chip away at the material(s). CNC lathes can be configured to cut precisely and efficiently. Such precise cuts would not be possible if done manually.

CNC Plasma Cutter

Plasma Etching is the elimination of silicon, plastic, or other non-metallic materials using plasma which is produced by exciting ions in a gas; typically oxygen and CF4. Those ions crash into the material at an atomic level and remove it without needing chemical acids. Within CNC plasma cutters, gas will be blown from a nozzle to the surface at very high speeds. Gas is then converted into plasma, with a temperature up to 50,000 degrees.

CNC Laser Cutter

CNC laser cutters are very similar to CNC plasma cutting machines. The biggest difference between the two, of course, is the use of the laser for cutting purposes. Lasers are tremendous tools used to cut metals, hardwoods and plastic materials. The intensity of the laser can be adjusted depending on the strength and density of the materials that needs to be cut.

Electric Discharging Machine (EDM)

Electrical discharge machines (EDM) use a nontraditional technique where material is removed from a workpiece via thermal energy. A lot like processes such as laser cutting, EDM doesn’t require mechanical pressure in the removal process.

The Two Different Sub Types Of EDM’s:

- In wire electrical discharge machines, a slim single-strand metal wire, is slipped across the piece. This wire will be submerged in a bath of dielectric fluid, generally deionized water.

- Electrical Discharge Machine or sinker EDM machining processes an electrically charged electrode calibrated to a particular configuration to burn the configuration of the electrode into a metal element. This type of process is usually used to produce molds and dies.

East Valley Precision – Custom Machinery Specialists

East Valley Precision offers custom CNC Machining in the Chandler, Arizona and surrounding areas. When you need precision CNC machining and milling contact East Valley Precision. Call us at 480-288-6601 for more information or use our form for a quote.

How To Use A Wood Lathe

For beginners, using a wood lathe can seem like a daunting task. This post will cover how to use the wood lathe and all of its components.

Wood Lathe Components

Here is a complete list of parts to know:

Size

Lathe size is determined by two factors. One factor is measuring the distance from the center of the spindle to the surface of the bed (determines maximum diameter limit). Another way to figure out size is by measuring the distance from the end of the spindle to the inside end of the tailstock. This will tell you what the length of the piece should be.

Headstock

The headstock is located to the left when viewing from the front of the lathe. Essentially, the headstock is the business end of the lathe, creating power by the motor being applied to wood. Some headstocks can come fixed in place, while others may rotate a full 360 degrees. Some headstocks can travel down the entire length of the lathe, as well. All of these options give you the ability to turn larger diameter pieces.

Spindle

Spindles are powered by belts and pulleys, with wood attached to the piece. The spindle is threaded on the outside of the lathe. It is located here in order to accept various attachments and accessories. The accessories are typically held in place by a specific taper. Tapers will vary by size.

Toolrest

Adjustable by both height and rotation, the toolrest can be moved along the length of the bed. This is made possible by loosening the banjo, then retightening it to find the desired position.

Motors

Modern lathes will utilize electric motors, while others use a hydraulic motor instead. The motors can be configured as fixed speed, variable speed, A/C, D/C, electronic braking and single rotation. Many motors will use drive through pulleys.

Tailstock

Tailstock is found farthest from the headstock, although it can be moved and adjusted, if needed. There is a movable part which can be driven by a hand wheel/screw mechanism. This part is usually hollow and fitted with morse taper to accommodate accessories.

Bed

The bed is the part of the lathe on which everything is mounted. The bed can be constructed of timber, steel, machined cast iron or round tubes.

Accessories

Here are a few accessories that may come with your lathe: knockout bar, wrenches, center for the tailstock and a faceplate. It is possible to add another toolrest to your application.

How To Use A Wood Lathe Machine

This next section will cover how to set up and operate the wood lathe machine.

Setting Up Wood Lathe

Begin this process by properly setting up your wood lathe machine. Make sure the machine is completely switched off before setting it up. Organize the tools as you set up and utilize the positional holding of the toolrest, at this time. Choosing the correct tool-bit is crucial, as the wrong selection could end up damaging your piece. Dull bits can also cause damage, so make sure the bits are sharp and ready for use.

High-speed steel is typically recommended for blades. Blades constructed of materials like carbon steel can become dull in a very short period of time. It’s always best to cut into the wood to form a 90-degree angle, but this changes over time as you become more skilled using the machine.

Wood Lathe Operation

After set-up is complete, start the process of turning the machine at the recommended 90-degree angle. Use the tailstock wheel to get the tailstock into the optimal position. The stock you are working on needs to be above the spindle of the headstock and inside the spur center. Turning the wheel of the tailstock will get this in position for you.

Always ensure your stock is tight. When loose, this can fly off and cause major damage. The tool-rest needs to be in line with the stock, with a comfortable amount of distance between the bit and stock. Try for a distance of 3/4-inch. Turn your wood lathe on next. Start it in the lowest possible speed.

For future projects, the speed you choose will be directly related to the type of wood you are cutting. You will undoubtedly notice the amount of resistance against you when your tool-bit cuts into the wood. A lot of resistance is normal as you cut.

At this time, bits of the wood stock should start falling off. As you dive into the stock with your blade, make sure you cover all directions. Tool-bits will differ depending on the task, so try to practice on spare stock ahead of time.

Water Jet Cutting Services

East Valley Precision offers water jet cutting services near Phoenix & Chandler, Arizona. Contact East Valley Precision today!

Wood Lathe Parts

Identifying all the parts of a wood lathe is crucial, especially when first using this machine.

Parts Of A Wood Lathe

Here is a complete list of parts to know:

- Size

- Headstock

- Spindle

- Toolrest

- Motors

- Tailstock

- Bed

- Accessories

Size

Lathe size is determined by two factors. One factor is measuring the distance from the center of the spindle to the surface of the bed (determines maximum diameter limit). Another way to figure out size is by measuring the distance from the end of the spindle to the inside end of the tailstock. This will tell you what the length of the piece should be.

Headstock

The headstock is located to the left when viewing from the front of the lathe. Essentially, the headstock is the business end of the lathe, creating power by the motor being applied to wood. Some headstocks can come fixed in place, while others may rotate a full 360 degrees. Some headstocks can travel down the entire length of the lathe, as well. All of these options give you the ability to turn larger diameter pieces.

Spindle

Spindles are powered by belts and pulleys, with wood attached to the piece. The spindle is threaded on the outside of the lathe. It is located here in order to accept various attachments and accessories. The accessories are typically held in place by a specific taper. Tapers will vary by size.

Toolrest

Adjustable by both height and rotation, the toolrest can be moved along the length of the bed. This is made possible by loosening the banjo, then retightening it to find the desired position.

Motors

Modern lathes will utilize electric motors, while others use a hydraulic motor instead. The motors can be configured as fixed speed, variable speed, A/C, D/C, electronic braking and single rotation. Many motors will use drive through pulleys.

Tailstock

Tailstock is found farthest from the headstock, although it can be moved and adjusted, if needed. There is a movable part which can be driven by a hand wheel/screw mechanism. This part is usually hollow and fitted with morse taper to accommodate accessories.

Bed

The bed is the part of the lathe on which everything is mounted. The bed can be constructed of timber, steel, machined cast iron or round tubes.

Accessories

Here are a few accessories that may come with your lathe: knockout bar, wrenches, center for the tailstock and a faceplate. It is possible to add another toolrest to your application.

Water Jet Cutting Services

East Valley Precision offers water jet cutting services near Phoenix & Chandler, Arizona. Contact East Valley Precision today!

10 Cool Things To Make With A CNC Machine

From pocket knives to board games, this a list of 10 fun and unique items you can create at home with a CNC machine!

Phone Case

CNC machines will allow you to create custom and durable cases for any type of cell phone. Regardless of how many jacks, speakers, ports or cameras the phone has, these machines enable you to make a case fitting any phone. Add some custom engravings or names on the case to really make your creation stand out.

- Material needed for cut: Wood.

Coasters

Are you looking for a simple project when you are first starting out with your CNC machine? Try creating some drink coasters for the family kitchen or coffee tables. Feel free to experiment with several different shapes, sizes and patterns.

- Material needed for cut: Wood.

Engravings

Do you want to make a keychain or some sort of keepsake for yourself or as a gift for a friend? Use your CNC machine to create a custom engraving. The beauty of this process is you can use pretty much any material you’d like for the creation. We suggest using wood or metal, but plastic and acrylic materials will work as well.

- Material needed for cut: Wood, Metal, Acrylic Or Plastic.

Pocket Knives

Much like creating a CNC yoyo, a pocket knife is a project that can take a long time and require precision at all times. Sharpening the metal will require focus, but it will make you more efficient with the machinery in the long run. Get the essential parts done first, then enjoy the creativity involved with engraving the outsides.

- Material needed for cut: Metal.

Board Games

Make your board game collection unique by creating pieces yourself. Use metal to make a chess board that is distinct from others. Games, such as chess, monopoly and snakes and ladders are perfect projects.

- Material needed for cut: Wood Or Metal.

Jewelry

While most DIY’ers tend to use metal for any jewelry creations, it is possible to turn wood into a piece of jewelry, as well. With CNC machinery, you can create rings, bracelets, earring, necklaces and more! Save money this holiday season by making your own jewelry for loved ones.

- Material needed for cut: Wood Or Metal.

Yoyo

This is one of the more unusual items one can make, yet one that can be passed down from generation to generation. Creating a CNC yoyo can be a bit difficult, though. You’ll want to weigh and balance the metal for optimum performance, while also making sure the string fits tightly around the ball bearings.

- Material needed for cut: Metal.

Signs

Typically, we suggest using wood as your material to create a sign with a CNC machine. Signs can create a great first impression as you enter a home or workplace. Make your area stand out with a wood sign that includes a greeting or quote.

- Material needed for cut: Wood.

Item Holder

No matter what you have in your home, garage or backyard, everyone could use an additional place to put some miscellaneous items. Too many times we will misplace keys, glasses, etc. Make sure that never happens again by building an item holder with your CNC machine. A nice piece of wood with several holes, rings and shelves could keep all of your small items organized.

- Material needed for cut: Wood.

Gift Boxes

Gift boxes are generally pretty simple to create, and the result can be truly magnificent. A well-crafted gift box can be used for years. Plus, you can turn the box into a storage box or container in addition to a gift box.

- Material needed for cut: Wood.

CNC Machine Shops Near Me

Do you want CNC machining services instead of attempting these projects on your own? Well, East Valley Precision, based in Chandler, Arizona, is here to help!

Equipped with over 40 years of experience, East Valley Precision has been offering top-notch customer service and machinery work throughout the valley. EVP specializes in CNC milling, turning, surface grinding, engineering and water jet cutting. This company also has extensive experience in machining aluminum, stainless steel, titanium and plastics. With customers from the medical, semiconductor and pharmaceutical industries, you can rest assured that any of your needs can be taken care of by EVP.

East Valley Precision – Custom Machinery Specialists

East Valley Precision offers custom CNC Machining in the Chandler, Arizona and surrounding areas. When you need precision CNC machining and milling contact East Valley Precision. Call us at 480-288-6601 for more information or use our form for a quote.