What is Wire EDM?

What is Wire Electrical Discharge Machining?

Wire electrical discharge machining (Wire EDM) utilizes a metallic wire for cutting or shaping workpieces, usually conductive materials, with a thin electrode wire that tracks a specifically programmed path. Usually, the electrode widths vary from .004″ to .012″, nevertheless smaller and larger widths are ready for use.

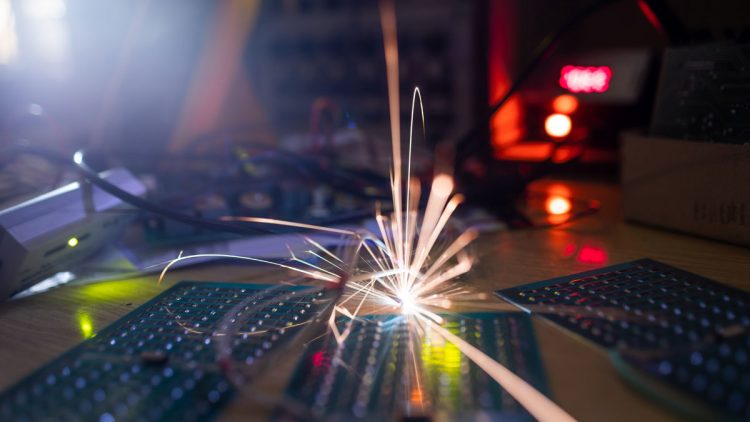

Throughout the wire cutting process there isn’t any direct contact between the wire and the work piece allowing for machining without causing any deformation in the wires path, or the shape of the material. For accomplishing this, the wire is quickly charged to a required voltage. The wire is also encompassed by deionized water. As the voltage reaches the proper degree, a spark hops the gap and melts a minute part of the work piece. The water cools then removes the minute leftovers from the gap.

The solidity of the work piece material has no damaging impact on the cutting speed. Blanking punches and extrusion dies are frequently machined via wire cutting.

The Way Electrical Discharge Machining Works

The primary EDM process is quite basic. A spark is created between 2 electrodes. The tool electrode is usually known as the electrode, and the work piece electrode as the work piece. The spark is visual evidence of the stream of electricity. This electrical spark produces intense heat with temperatures hitting 8,000 to 12,000 degrees Celsius, melting/vaporizing just about any conductive material. These swift, recurring electrical current discharges happen in a very tiny gap between the 2 electrodes, in which never come in contact with one another. The spark gap is managed by adaptive device controls to guarantee a continual, balanced distance as the electric discharge happens up to millions of times every second.

The spark is very specifically managed and restricted, so it only impacts the face of the material. This process typically does not impact the heat treat underneath the face. Both the tool and workpiece are immersed in dielectric (un-conductive) fluid, usually deionized water.

The spark always happens in the dielectric fluid. The conduction of the deionized water is cautiously overseen, creating a perfect setting for the EDM process. The deionized water additionally provides cooling throughout the machining process, and eradicates the small, eroded metal fragments.

EDM is considered a non-conventional machining technique since it uses electric discharge for removing material from the work piece. This contrasts with conventional machining techniques like grinding or drilling which use mechanical force for removing material.

What Types of Shapes Can A Wire EDM Machine Produce?

Wire EDM machines are a kind of CNC machine that can move along four independent axis to create taper cuts. For instance, a stamping die can be created with 1/4-degree taper or a mold with 1 degree taper in some areas and two degrees in others accurately. Extrusion dies or horns and nozzles can be cut with continually changing tapers. For instance, an intricate shape on top of the work piece can shift to a simple circle at the bottom.

Uses for Wire EDM Cutting

East Valley Precision’s wire cut EDM services are perfect for fragile or small work pieces that might be damaged throughout traditional machining or other conventional methods:

- Thicker parts requiring pristine finishes and/or accuracies.

- Intricate shapes or slender slots

- Large components that need to hold accurate allowances

- Fragile, hard, exotic/costly or weak materials

East Valley Precision – Custom Machinery Specialists

East Valley Precision offers custom CNC Turning in the Chandler, Arizona and surrounding areas. When you need precision CNC turning and milling contact East Valley Precision. Call us at 480-288-6601 for more information or use our form for a quote.