Benefits of CNC Machining

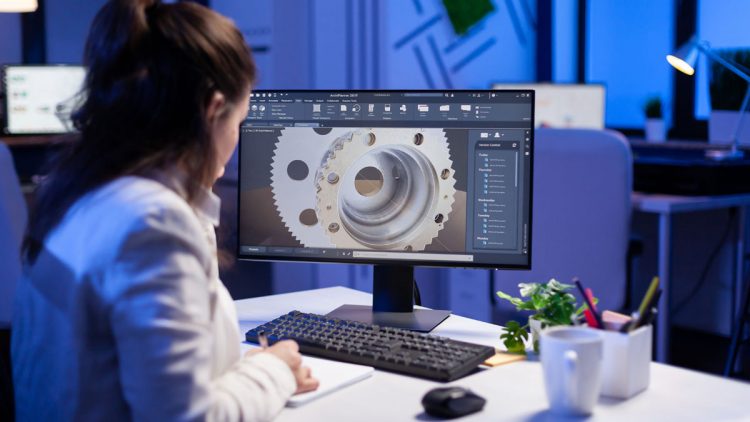

CNC machining is a fabrication method that utilizes computer-aided devices to cut metal or other materials into complex shapes and patterns. It provides many distinctive benefits that make it an invaluable technology for a broad range of industries.

Among the exceptional CNC machining benefits for machinists is that it enables them to redesign and re-shape existing workpieces without having to start from the beginning. When they do create a workpiece from scratch, they do so via CAD software which allows them to make very complex designs with nominal wasted material. This method of machining can decrease waste and save money because of the computer’s proficiency and automation, rather than relying on human operation. Added worthwhile differences make themselves obvious subject to the application. In this post, it will explore some of the primary CNC machining benefits.

CNC Machining Produces Minimal to No Waste

CNC machining is not only productive, but it also can decrease material wastage due to its exactness and precision. Provided that the workpiece is designed correctly on the computer, the machine itself is probably never going to make a faulty cut, so there are going to be fewer damaged workpieces for removal. The machine can manage precise cuts and angles without producing much waste.CNC Machining Is More Precise and Is Defect Free

One of the significant CNC machining benefits is precision. Since CNC machines receive precise guidelines from a computer — and the movements are similarly implemented under computer management — their results are going to be identical every time and is going to match the computer model closely. This is a considerable advantage in terms of creating workpieces with tight tolerances. This proficiency almost completely eliminates human error out of the equation.CNC Machining Provides More Quick and Effective Production

Another industry-dominating CNC machining benefit is the essential speed and efficiency of production. These machines are capable of producing products much faster and more efficiently than conventional methods. Many of today’s units can even load the billet and unload the completed workpiece without human interference. Naturally, this capability leads to considerable cost savings and rising productivity. Additionally, this type of automation makes workpieces more consistent.CNC Machining Makes Assembly Quicker

Products in which components are created under computer numerical control are easier to assemble. Since CNC machining is so accurate and consistent, companion parts are going to fit together exactly as they show on the computer. And because the process is faster than manual machining, you are going to spend less time waiting for workpieces to be finished. Unless there is an issue in the computer model, all workpieces should fit together precisely. This capability can save a lot of time and money throughout the assembly process, as there is not a requirement for comprehensive fitting and adjustment.CNC Machining Isolates Machines from People and Decreases the Risk That Would Otherwise Come Up

CNC machining eliminates considerable safety risks from the shop floor. By automating the machining process, it eliminates many of the risks associated with manual machining. Additionally, CNC machines are usually enclosed, which further decreases the risk of injury.CNC Machining Uses Little Energy

CNC machining consumes less electricity than older methods, as a result decreasing energy use. As reported by the EPA, CNC machining uses around 14% of the energy of conventional machining techniques. There are several reasons; These machines not just work fast but consume less power each minute than other fabricating methods.CNC Machining Can Decrease Production Expenses

CNC machining is a budget-friendly, efficient, and accurate process of fabricating workpieces and products. This type of machining also uses less raw materials compared to conventional machining. Focusing your shop on CNC technology is going to drastically decrease errors, production spending, and product expenses.East Valley Precision – Custom Machinery Specialists

East Valley Precision offers custom CNC Machining in the Chandler, Arizona and surrounding areas. When you need precision CNC machining and milling contact East Valley Precision. Call us at 480-288-6601 for more information or use our form for a quote. 0